A Thorough Dive into CAT Excavator Substitute Components

As for industrial machines, Caterpillar's excavator line are famous for one’s strength, capability, and reliability. Such robust machines are vital in various industries, from infrastructure development to excavation, since they tackle demanding tasks with effectiveness. However, like any equipment, wear and tear is inevitable over the passage of time, causing the necessity for replacement parts to preserve peak efficiency. Grasping the importance of quality Cat parts is essential for users and businesses aiming to limit operational delays and lengthen the longevity of their excavators.

Substituting worn-out components with genuine Caterpillar parts guarantees that your machine operates at maximum performance. The right parts also improve performance but also enhance the security and lifespan of the tools. In this exploration, we will look into the various types of Caterpillar excavator components, the benefits of choosing genuine Cat parts , and advice for sourcing them effectively. Whether you’re a seasoned operator or just entering the world of large machines, knowing the details of Caterpillar excavator parts will enable you to choose wisely for the tool necessities.

Categories of Caterpillar Excavator Replacement Parts

Cat excavator are sophisticated devices composed of various elements that can deteriorate or become damaged over the years. One of the most important types of replacement parts is the motor components, which include pieces such as air filters, o-rings, and timing belts. These components are essential for ensuring the performance and efficiency of the excavator. A well-functioning engine ensures that the machine operates smoothly and minimizes failures, which is vital for any construction job.

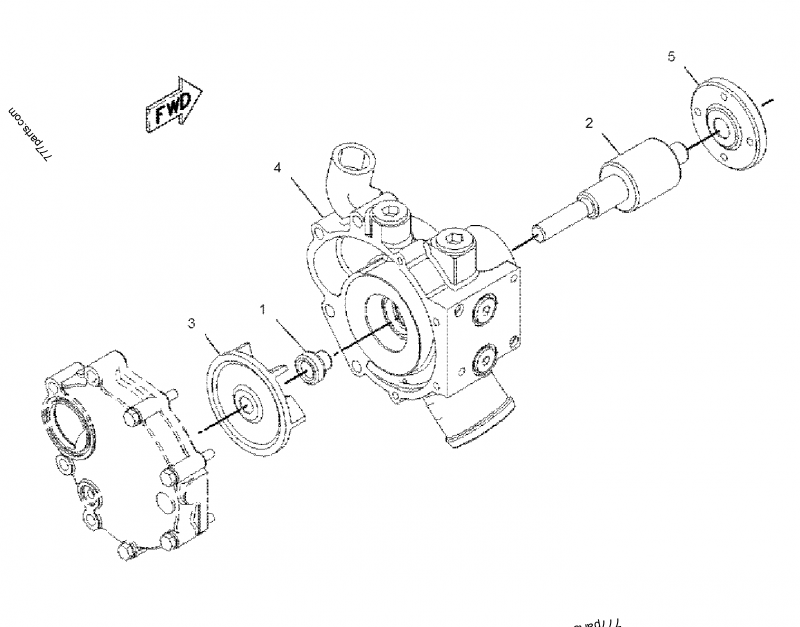

The hydraulic mechanism in a Caterpillar excavator is another area where replacement parts are often necessary. Parts like pumps, actuators, and hoses play critical roles in the functioning of the machine. Hydraulic systems are responsible for lifting heavy loads and providing the necessary force for various attachments. Regular maintenance and prompt replacement of these components help in maintaining optimal hydraulic performance, guaranteeing that the machine can handle demanding tasks without concerns.

Undercarriage components are also crucial for Cat excavator, as they impact the mobility and balance of the equipment. Parts such as treads, idlers, and cogs are critical for adequate movement across different terrains. Over time, these parts can suffer damage, leading to reduced efficiency and higher likelihood of breakdown. Investing in high-quality spare tracks and undercarriage components is essential for ensuring the longevity and performance of the excavator.

Opting for Superior Replacement Parts Parts

When it comes to picking replacement parts for your Caterpillar machine, quality should be your primary focus. The performance and durability of your machine heavily rely on the parts you select. Using top-notch Cat parts not only guarantees optimal performance but also enhances the safety of your workflow. Poor-quality components may lead to regular failures, increasing downtime and repair costs. Investing in reliable brands or OEM components can greatly reduce these risks.

Moreover, you should consider is compatibility. Ensure that the components you choose are tailored designed for your specific Caterpillar machine. Mismatched components can cause problems and even harm to the machine. Always check the specifications and speak with a experienced supplier to confirm that the parts will fit and function properly within your excavator's system.

Lastly, consider the vendor’s reliability. Working with established suppliers who focus on Caterpillar parts can provide confidence. Look for suppliers who provide warranties or assurances on their products, as this can be an sign of their assurance in quality. A reliable supplier will also be able to guide you on the most suitable components for your requirements, ensuring you make informed decisions that keep your excavator operating efficiently.

Maintenance Tips for Caterpillar Excavators

Regular care is essential for the longevity and performance of Cat excavators. One of the first steps is to establish a systematic check timing. This must consist of checking liquid amounts, such as oil, coolant, and hydraulics fluids, to make sure they are at optimal levels. Additionally, keeping an eye on filters and changing them when required can avert significant issues and keep the excavator operating efficiently.

A further important aspect of upkeep includes inspecting the tracks and undercarriage for damage and deterioration. Ensure that the tracks are correctly tensioned and free from obstruction, as this can impact movement and lead to unneeded wear. It is also essential to maintain the lubrication points frequently and apply lubrication when required to minimize friction and wear on mechanisms.

In conclusion, putting resources into genuine Cat components during substitutions can considerably enhance the efficiency and reliability of your excavator. Using original equipment manufacturer parts ensures compatibility and quality, which can consequently save expenditures related to repairs and downtime. Think about collaborating with a licensed dealer or service provider for obtaining parts and servicing, as they have the skill to keep your equipment in ideal condition.